The field of materials engineering includes the following topics

The mechanical materials testing laboratories are used to analyse material samples to determine their mechanical properties. Materials are tested for strength, ductility, hardness and toughness both at room temperature and under the influence of temperature. In addition, tests can be carried out to determine the fatigue strength in order to evaluate the behaviour of the materials under repeated loading.

TIRA TT28100

- electromechanical tension and compression testing machine with max. load of 100 kN

- load cells for 5 kN, 20 kN and 100 kN

- test area dimensions 1250 x 580 mm

- measured value acquisition rate up to 5 kHz

- crosshead travel resolution 0.001 mm

- crosshead speed 0.01 - 500 mm/min

- HSR climatic chamber for temperature range from -80°C (liquid nitrogen) to 600°C

- Maytec HTO-34 high-temperature furnace for max. temperature of 1200°C

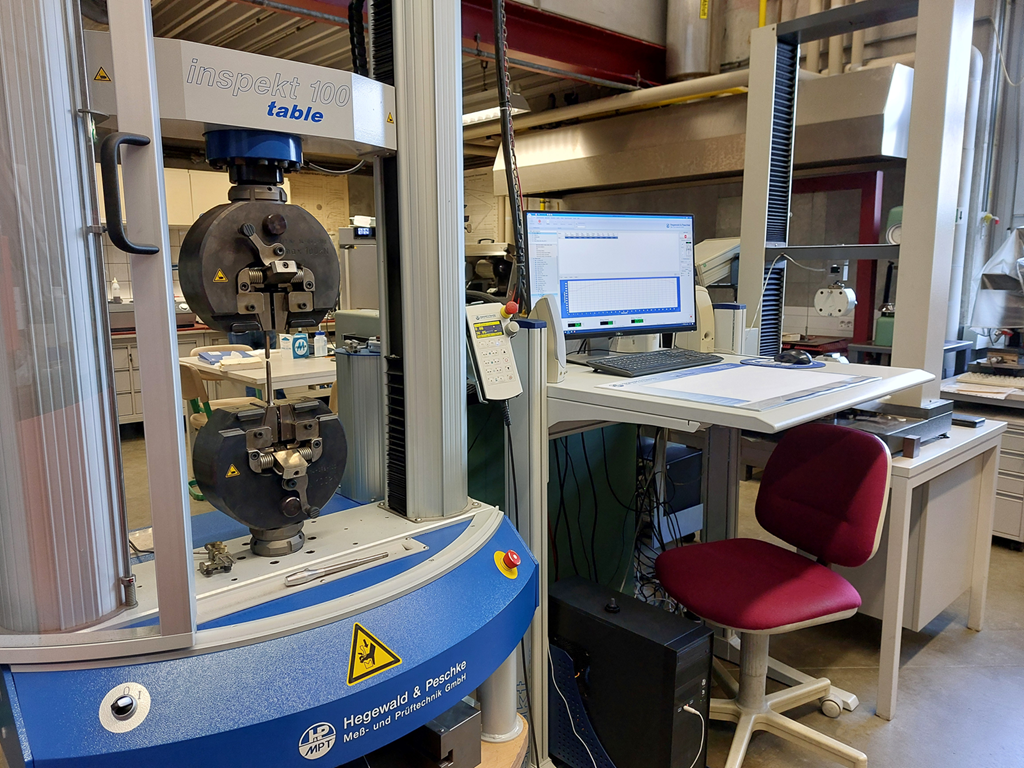

Material Test System MTS 810

- hydraulic tensile and compression testing machine with a maximum load of 250 kN for static and dynamic tests

- test chamber dimensions 210 x 630 mm

- setup for bending tests available

- hydraulic chucks for flat and round specimens

- universal servo hydraulics for various complex testing tasks, such as component testing

- frequency (for cyclic fatigue testing) – 10 Hz

- test stroke ±75 mm

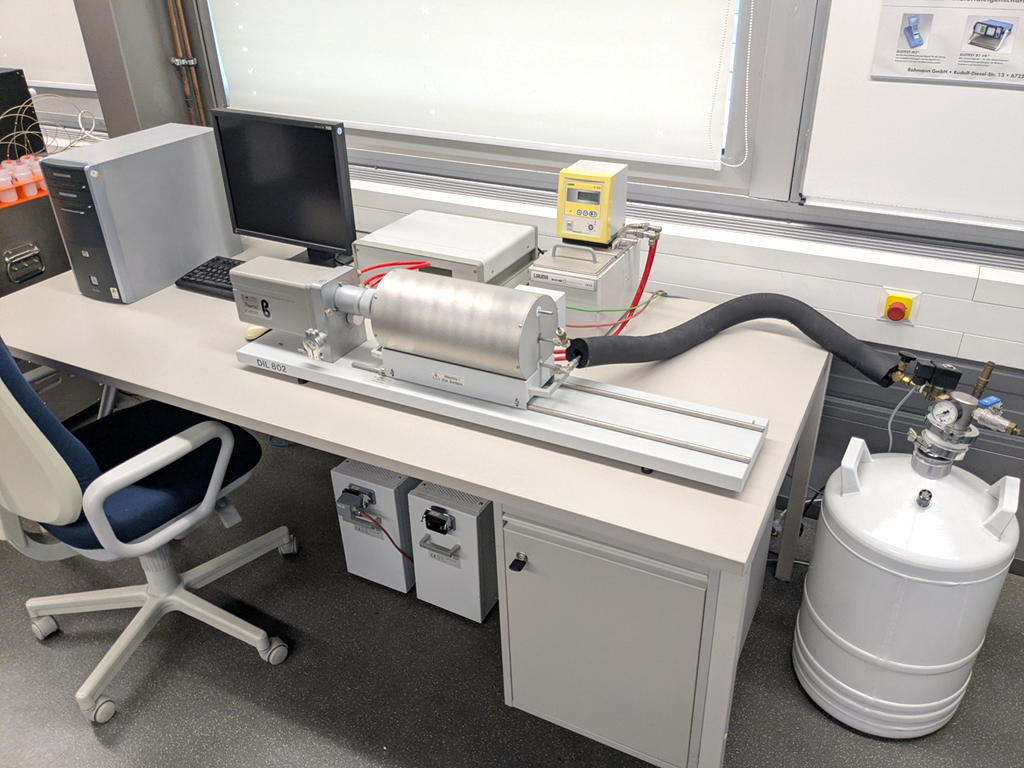

The laboratory for non-destructive material testing offers comprehensive analyses of the quality and integrity of materials. In addition to surface crack testing to detect the finest crack formations, the range of services includes the testing of internal defects using modern methods and dilatometry to determine the thermal expansion and transformation properties of materials. Materialography includes the careful preparation of samples and the creation of micrographs to visualise material structures. Subsequent characterisation provides important insights into the structure, properties and quality of the materials.

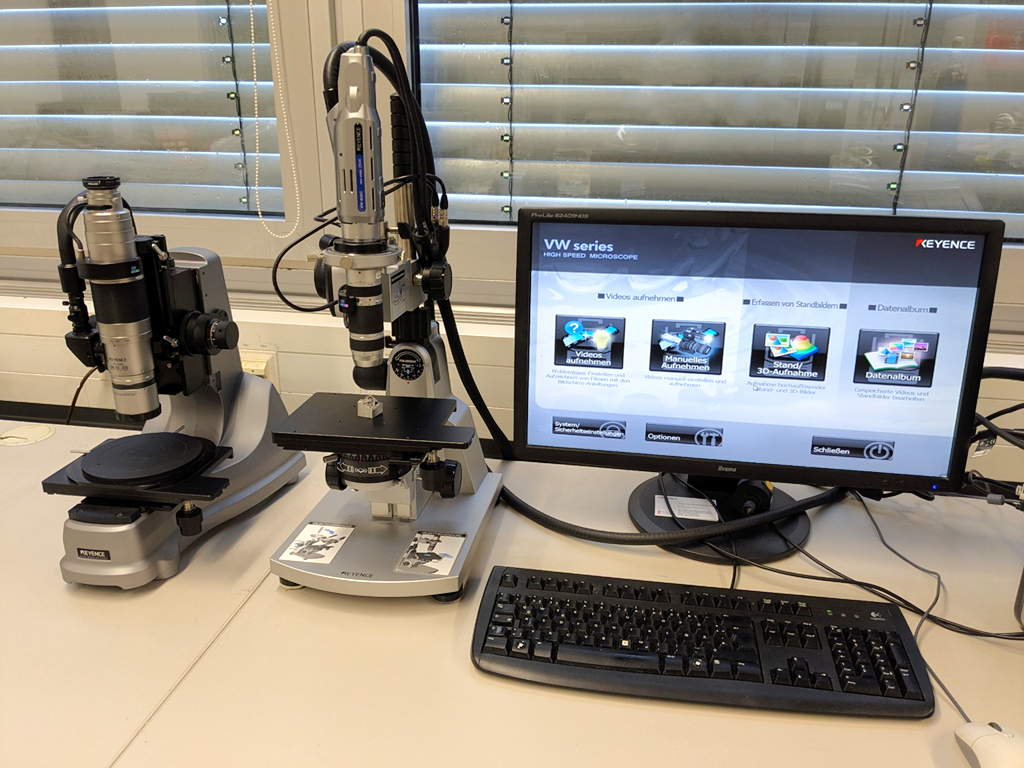

Keyence VW-9000

- modular digital microscope with high-speed camera

- VH-Z20R standard zoom objective 20x to 200x

- VH-S30B stand for viewing from any angle with motorised Z-axis

- multifocus 3D measurement

- VH-Z250R zoom lens for high magnifications 250x to 2500x

- VH-S5 vibration-resistant stand for high magnifications

- VW-600C high-speed colour camera with up to 230,000 fps

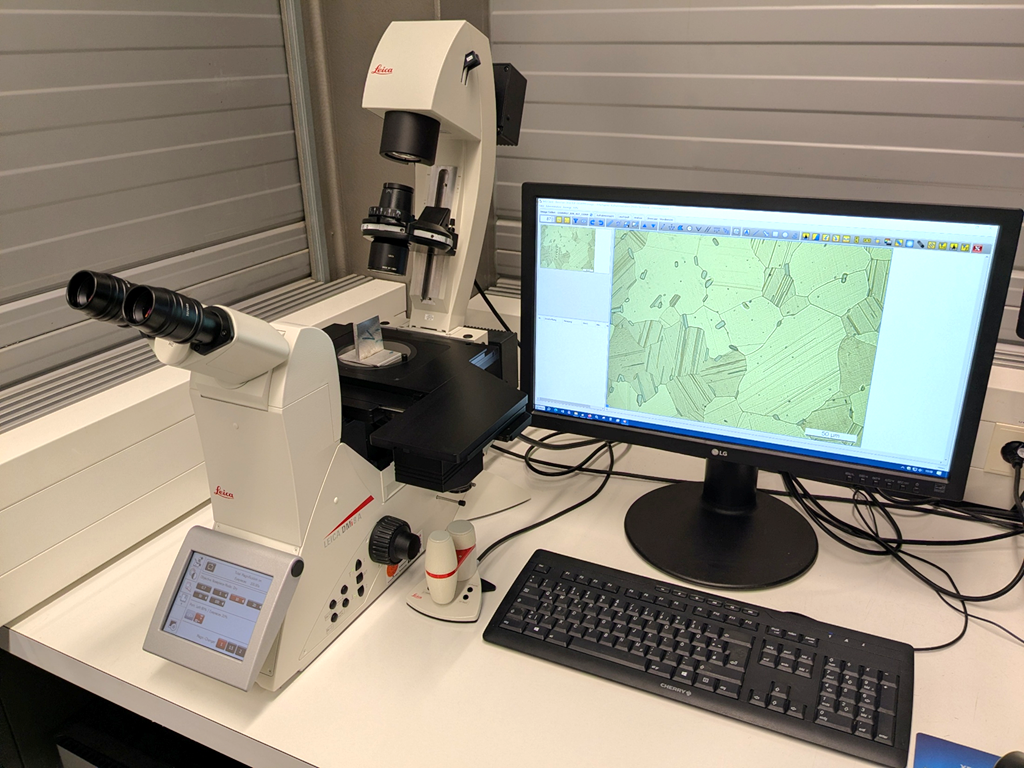

Leica DMi8 A

- inverted reflected light and transmitted light microscope with max. magnification of 2000x

- motorised X-Y stage for oversize images

- automatic multifocus for high depth of field

- brightfield, ultra-contrast 3D, darkfield, differential inference, polarisation and fluorescence contrast methods reflected light and phase contrast microscopy transmitted light

- iMagic IMS analysis software for grain size, phase and particle determination as well as manual image processing and measurement

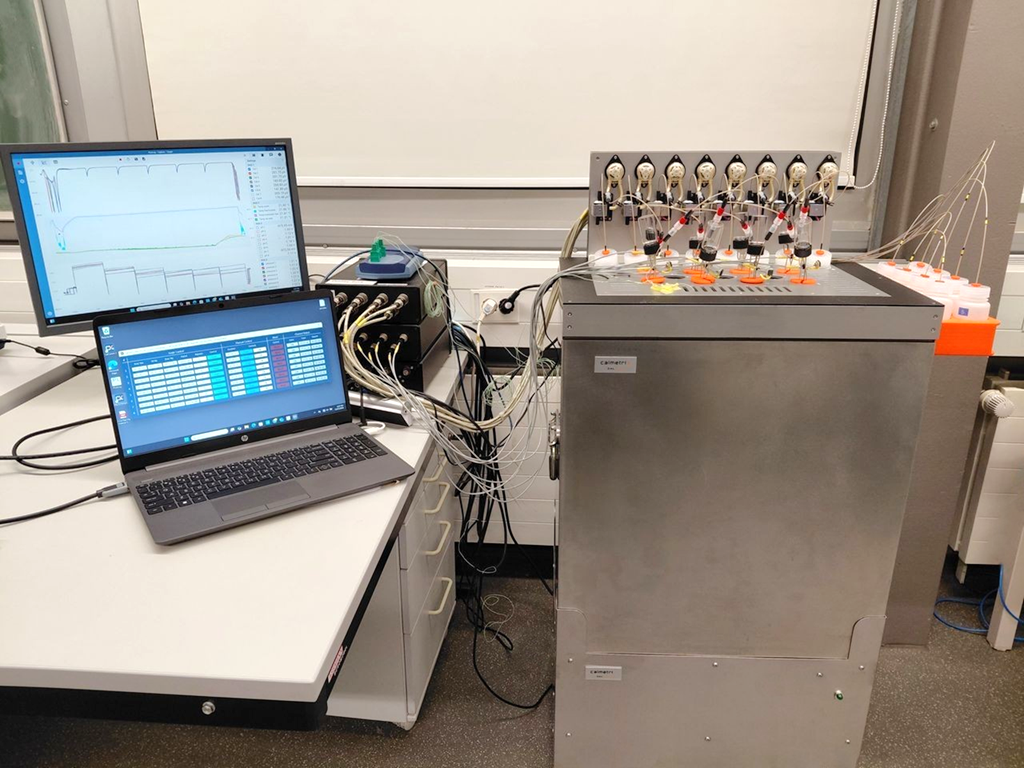

Calmetrix I-Cal Flex

- isothermal 8-channel calorimeter for material characterisation, separate measuring cells

- 20 ml measuring volume per channel with liquid exchange at intervals via pump system

- continuous pH value measurement

- low noise and high sensitivity, ideal for weak reactions

- temperature range from approx. 2°C to 90°C

- for applications such as polymerisation of plastics, curing of adhesives, corrosion of Mg alloys, battery materials, cement

- determination of the corrosion rate of Mg alloys via individual pressure measurement per cell

devices for materialography

ATM Q-Pol 250 M2 grinding and polishing machine, twin spindle

- speed continuously adjustable from 30 to 600 rpm

- working disc diameter 250 mm

- centrifugal function

Struers TegraPol-21 wet grinding and polishing machine with TegraForce-5 (motor-driven specimen holder)

- working disc diameter 250 mm

- speed continuously adjustable from 50 to 300 rpm (polishing disc)

- up to 6 specimens (Ø 40 mm) can be prepared simultaneously

- speed continuously adjustable from 50 to 150 rpm

Struers Rotopol 1 wet grinding and polishing machine

- two-spindle

- working disc diameter 230 mm

- speed 150 or 300 rpm

precision cutting machines

cold embedding equipment

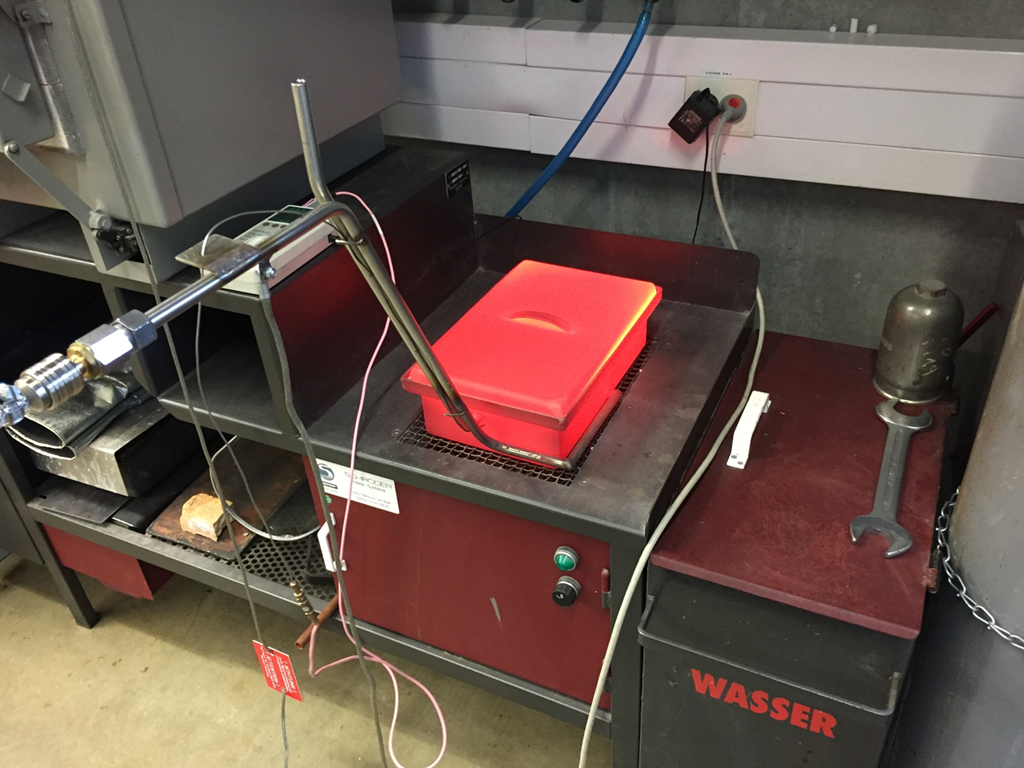

During heat treatment, materials are specifically heated and cooled to change their properties. Precise temperature control is made possible with the help of chamber furnaces and various quenching media. This allows hardness, strength and toughness to be adjusted and adapted to the respective technical requirements.

Nabertherm LT 40/12

- muffle furnace with max. temperature of 1200°C

- temperature uniformity according to DIN 17052-1 up to +/- 5 K

- internal dimensions 320 x 490 x 250 mm

- volume 40 litres

- parallel swing door opening upwards

- heating timeTR - 1100°C approx. 97 min

- controller for precise programming of temperature control

- protective gas connection for purging the oven with non-flammable process gases

Nabertherm gas flushing and annealing box for N 11/H

- max. operating temperature of 1100°C

- ceramic fibre seal

- gas supply box for non-flammable protective and reaction gases such as argon, nitrogen and forming gas

- type K batch thermocouple for temperature display or batch control

- pre-purge rate 15 - 20 l/min and process purge rate 5 - 8 l/min

- annealing box for carburising and powder nitriding

- internal dimensions 180 x 290 x 90 mm

Memmert UF110

- drying oven with working temperature range min. 10 K aboveTR to max. 300°C

- setting accuracy up to 99.9°C: 0.1 and from 100°C: 0.5

- interior dimensions 560 x 480 x 400 mm

- volume 108 litres

- target time adjustable from 1 min to 99 d

- adjustable air circulation motor speed, exhaust air flap position, programme run time, time zones, summer/winter time

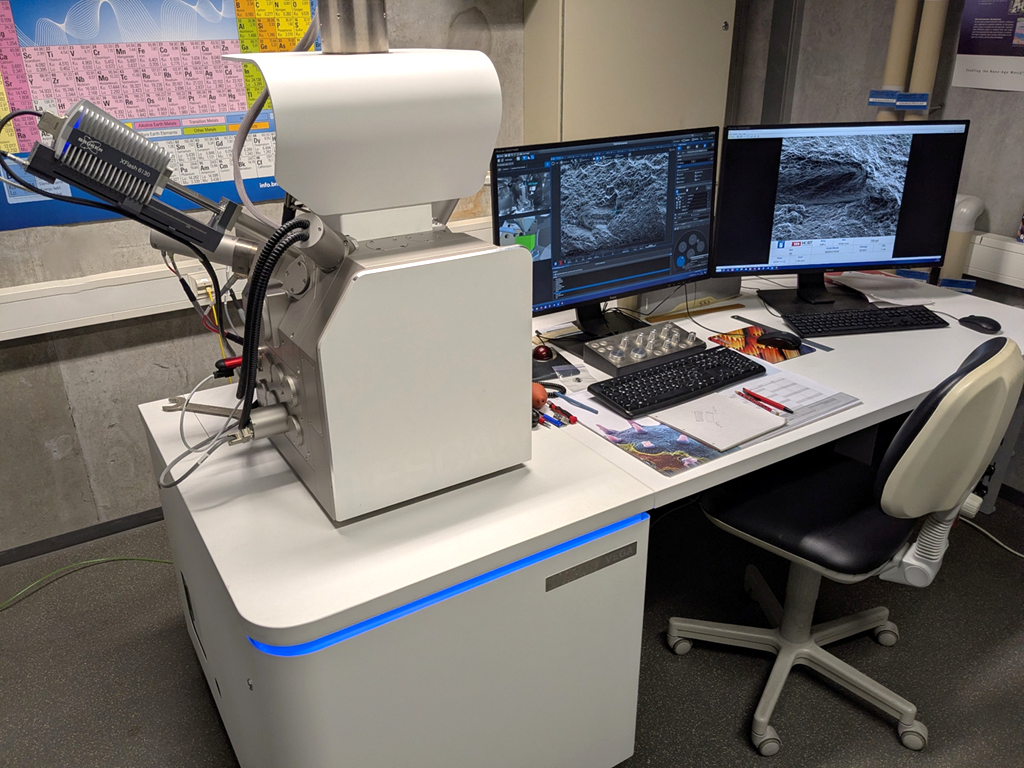

Materials are analysed in detail in the scanning electron microscopy and computed tomography laboratories. The scanning electron microscope enables high-resolution imaging of surface structures and the analysis of chemical compositions. Computed tomography is used for the non-destructive three-dimensional visualisation of internal structures and defects in materials in the micrometre range.

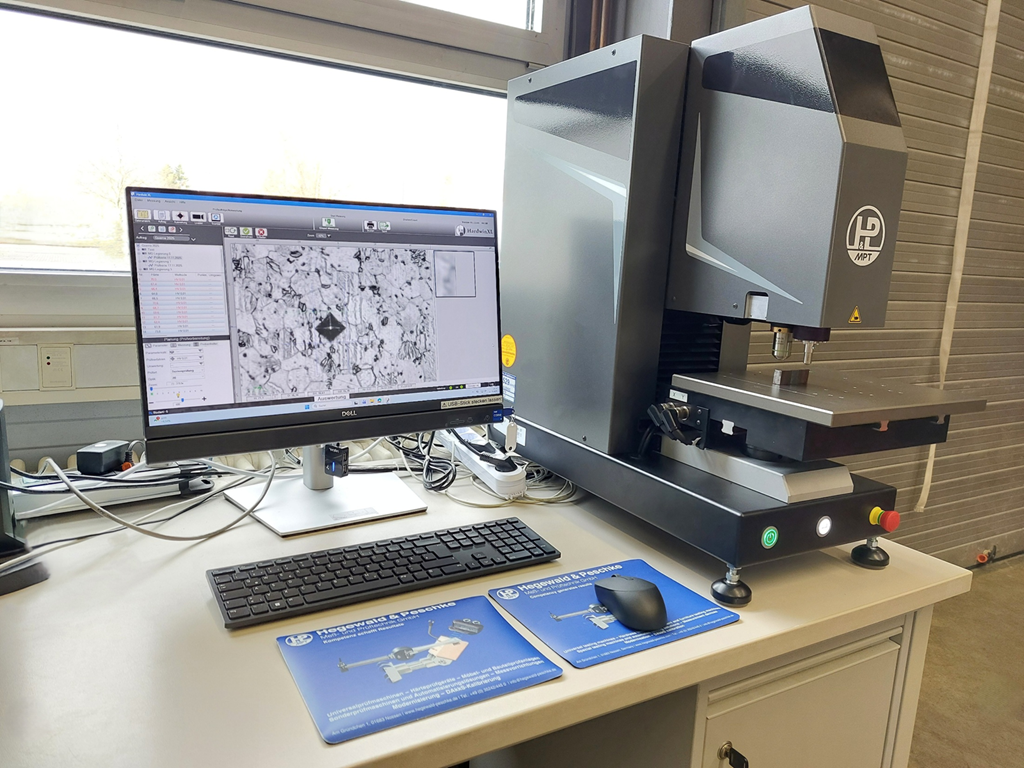

Tescan VEGA

- scanning electron microscope equipped with SE, BSE and EDX detector

- acceleration voltage 200 eV - 30 keV

- infinitely adjustable beam current 1 pA - 2 µA

- wide-field and high-resolution mode

- low-vacuum operation for non-conductive or aqueous samples

- maximum field of view of 7.7 mm at a working distance of 10 mm, more than 50 mm at maximum working distance

- infinitely variable magnification from 2× to 1,000,000×

- maximum sample dimensions of 54 (H) x 145 (X) × 145 (Y) mm

Bruker Skyscan 2214

- multiscale 3D X-ray nanotomography (XRM) with resolution in the sub-micrometre range

- objects up to Ø 300 mm and length up to approx. 400 mm

- modular flat-panel and CCD detector design with filter magazine depending on material and application

- very fine nanofocus X-ray source (< 500 nm voxel size)

- W (tungsten) and LaB6 (lanthanum hexaboride) filaments

- acceleration voltage from 20 - 160 kV

- maximum power of 16 W

- software-supported image acquisition, 3D reconstruction and analysis