The laboratories of the School of Mechanical Engineering are equipped with modern technical equipment that enables students to receive a sound and practical education. The close interlinking of theory and application means that future-relevant skills are specifically promoted. In addition, the faculty demonstrates a strong willingness to collaborate with partners from industry and research in order to drive innovation and successfully realise joint projects.

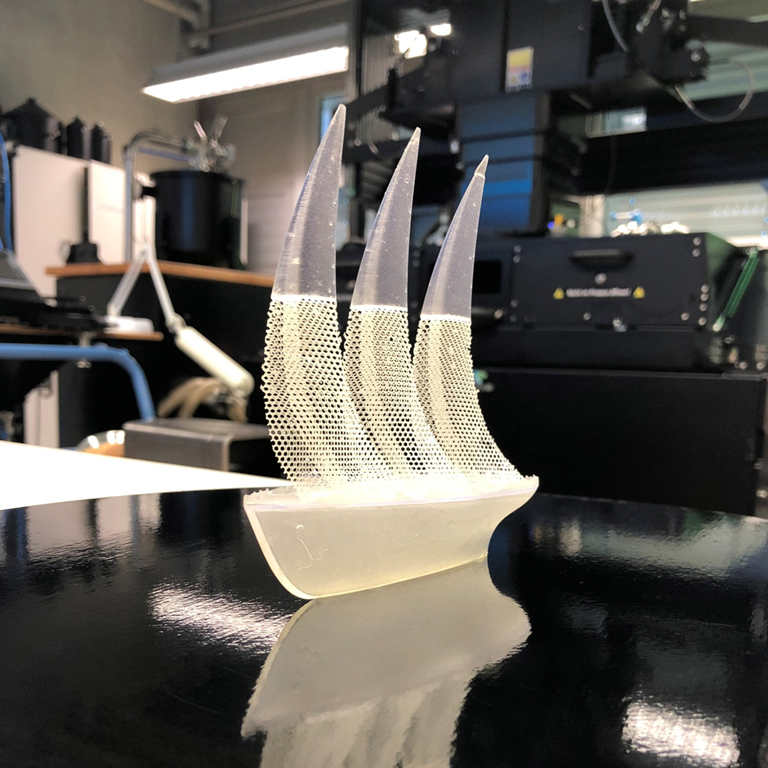

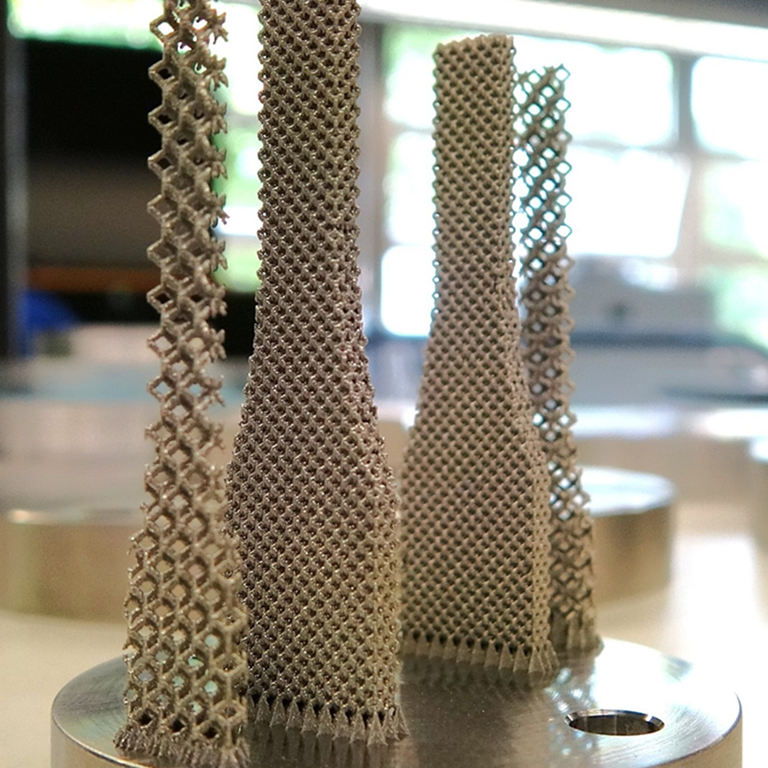

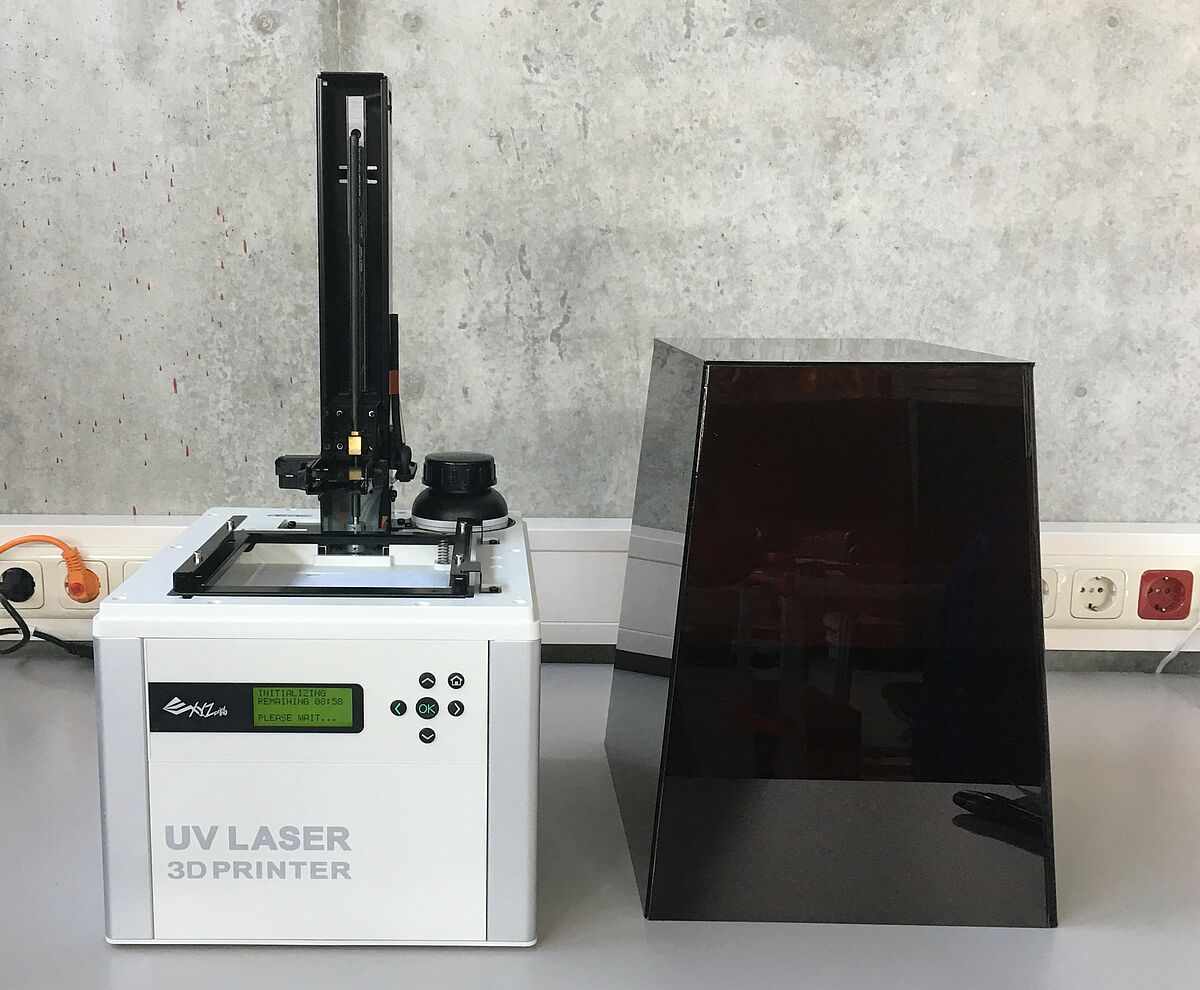

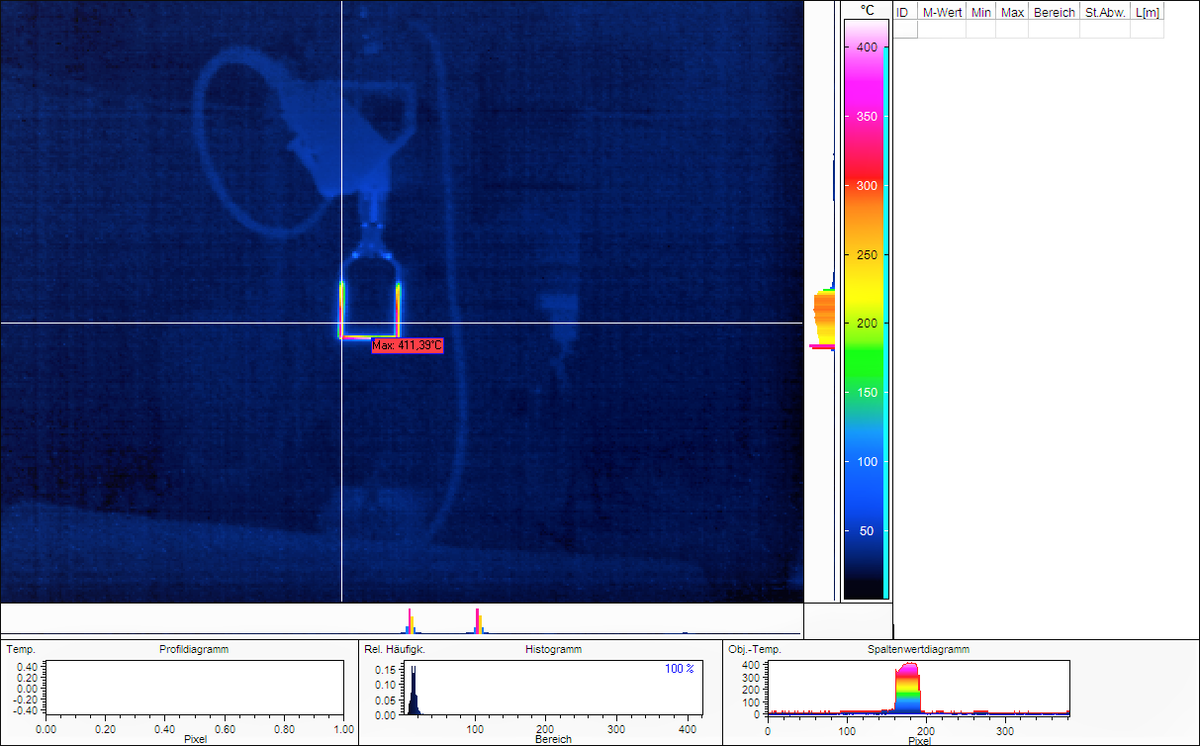

As part of projects in the laboratory for additive manufacturing & dig. Product Development Laboratory, students are able to identify tasks with requirements from research and/or industry and develop constructive and innovative solutions for them.

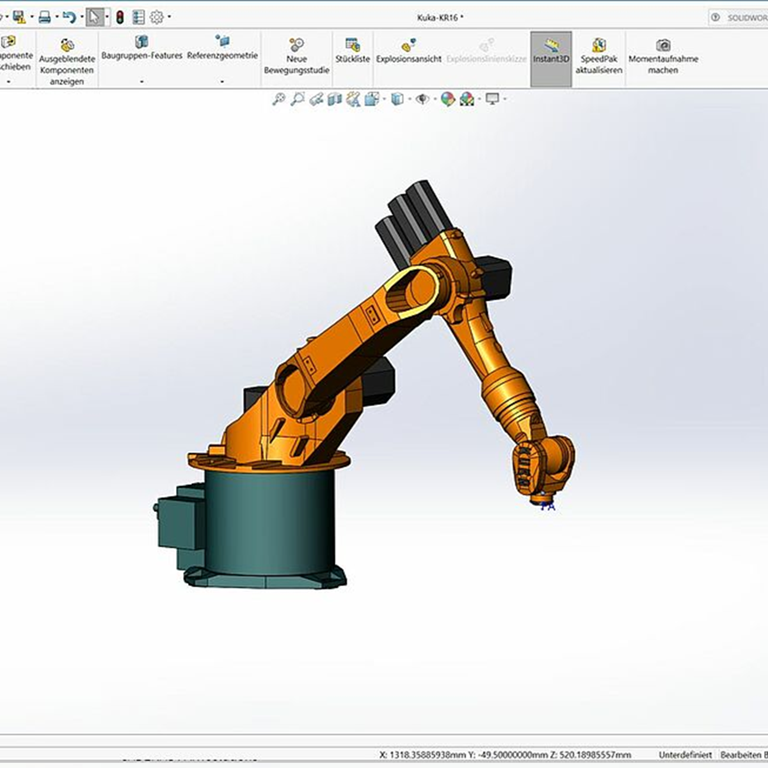

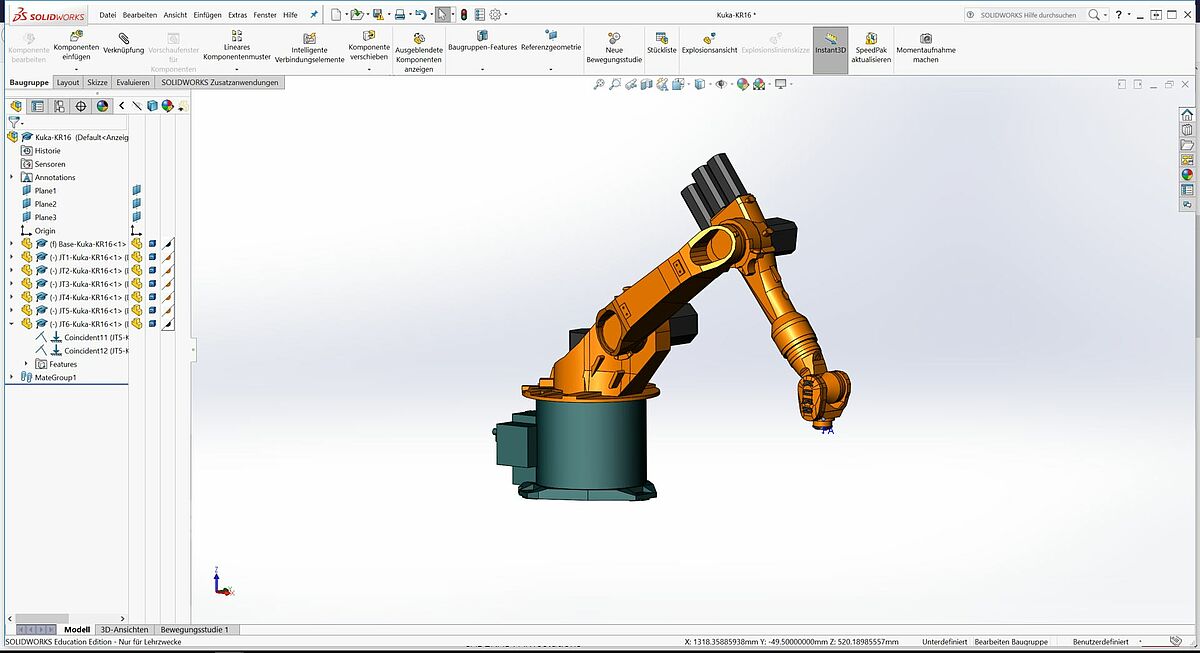

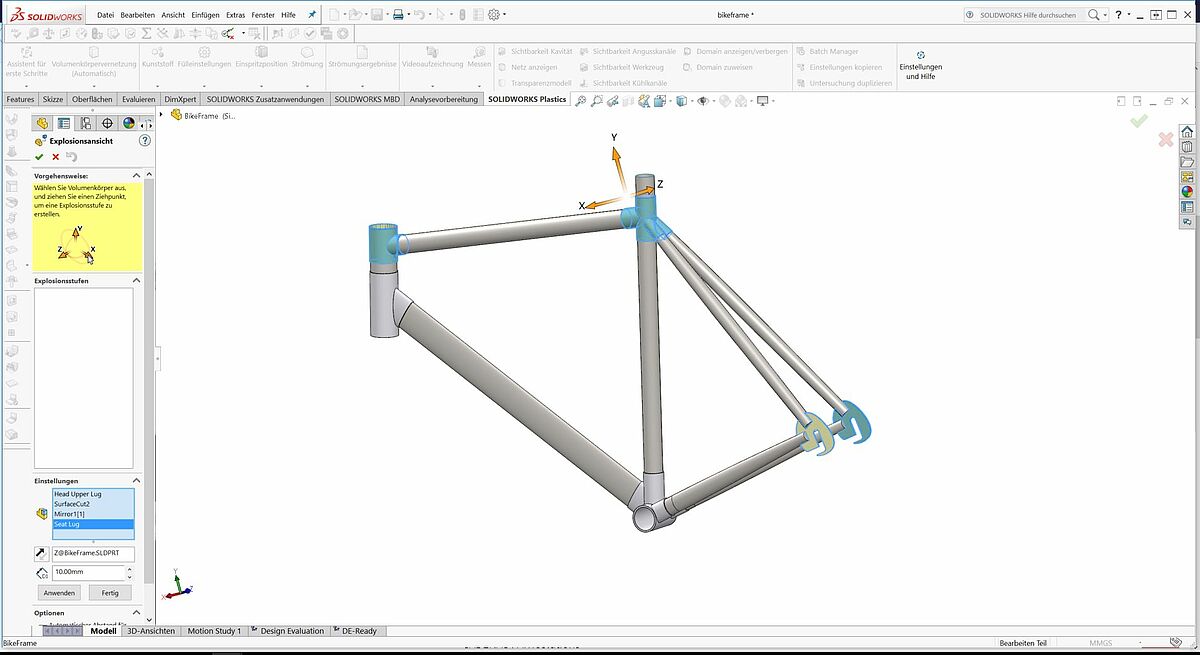

Practical projects are carried out in the areas of machine elements, design systematics, 3D CAD, robot-assisted manufacturing and additive manufacturing.

At the same time, the laboratory team is researching the development of materials and geometries for the application of additive manufacturing in healthcare technology.

Contact person:

Sven F. Klimaschewski (M.Eng.)

Laboratory extension: +49 3831 45-6905

Student team:

- Robert Raschke, B.Eng.

- Jan Siebenbürgen

Follow Lab on Instagram!

Equipment:

- 5 PC workstations for CAD software (SolidWorks)

- 1 industrial robot (KR16 and KR30) with milling and measuring equipment (KUKA AG, Germany)

- Replicator Z18 fused deposition modelling system (MakerBot Industries, U.S.A.)

- Stereolithography system Nobel 1.0 (XYZprinting Inc., Taiwan)

- Stereolithography system Form2 including Form Wash and Form Cure (Formlabs Inc., U.S.A.)

- Laser-sintering system for thermoplastics LISA (Sinterit sp.z o.o., Poland)

- Demonstrator Adaptive Frontlighting System - AFS (Automotive Lighting Reutlingen GmbH, Germany)

- Thermographic camera VarioCAM HD head (InfraTec GmbH, Germany)

- Creative workstations

Laboratory exercises:

The laboratory exercises are always related to current projects. Essential components are

- Sketching and designing (existing) components and building 3D models as an exercise sequence

- Designing assemblies with the 3D CAD software SolidWorks

- Generation of NC programmes for robots with RobotWorks and NC milling with Solid CAM

- Design of prototypes and production using additive manufacturing processes

- Creation of samples and prototypes as part of the 3D-CAD II lecture

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Analysis of fuels, water, soil and materials

Contact person:

Prof. Dr.-Ing. Matthias Ahlhaus

Equipment:

Wet chemical laboratory with 3 fume cupboards

Distillation apparatus

Density meters

viscometer

Analytical balances

Laboratory granulator Pulverisette 15

Ovens for drying and ashing

Calorimeter

Shimadzu TGA 51M thermogravimetric analyser

Atomic absorption spectrograph for trace metal detection

Carbon and sulphur apparatus for use in environmental and steel analysis

Potentiostat for recording current density-potential curves

Laboratory exercises:

Density and viscosity and distillation of liquid fuels

Determination of the water and ash content of solid fuels

Thermogravimetry

Determination of calorific and heating value

Corrosion behaviour of light metal alloys (immersion and polarisation/voltametry)

Stress corrosion and corrosion fatigue and its corrosion morphology

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

In the laboratory, students learn about the practical design of systems and system elements. The function and operation of special apparatus and pipework elements can be examined realistically on various test stands.

Contact person:

Equipment:

- Heating system

- Test stands with various heat exchangers

- Compact district heating station

- Heat flow plate

- Oil tank" trainer

Laboratory exercises:

- Design of a heating system

- Constructive design using the example of a 320 litre fermentation and storage tank

- Design of heat exchangers

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

The laboratory is used to train our students in lectures/seminars such as Machine Elements I + CAD, Design Systematics and 3D CAD I + II as well as Automotive Lighting Engineering and is also available to students for design work as part of their dissertations, projects and final theses.

Contact person:

Equipment:

The following equipment is available for use in PC-Pool I:

-

- 15 PC workstations with the following equipment:

-

- 2 x 24'' TFT monitor (IIYAMA, The Netherlands)

- Desktop PC, 3.4 GHz, 8 GB (Exone GmbH, Germany)

- Graphics card Nvidia Quadro 2000D (NVIDIA Corporation, U.S.A.)

- Cherry keyboard (Cherry GmbH, Germany)

- Laser mouse (Logitech international S.A., CH)

- SpaceMouse Pro (3Dconnexion GmbH, Germany)

- 1 Epson 2480 flatbed scanner (Seiko Epson Corporation, Japan)

- 1 b/w laser printer Kyocera FS 9130DN (Kyocera K.K., Japan)

- A0 plotter MBT920PS (HP Inc., U.S.A.)

- Full HD projector EB4850WU (Seiko Epson Corporation, Japan)

The latest version of the following software is available for use in the CAD lab:

-

- MS Windows operating system

- MS Office

- Corel Draw!

- SolidWorks

- SolidCAM

- RobotWorks

- CADENAS PARTsolutions

- Mathcad Prime

The laboratory is fully air-conditioned, a didactic PC training system (lecturer/student circuit) has been installed and the doors have been fitted with programmable transponder locks to ensure that they can be used 24/7 by our students.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

The "Computational Fluid Dynamics" laboratory provides knowledge in the modelling of thermofluid dynamic flows to accompany the lecture of the same name. Based on commercial CFD software (ANSYS Fluent), practical examples are used to demonstrate how to carry out various flow simulations. The aim of the laboratory courses is to develop a deeper understanding of transport phenomena (momentum, heat and mass transport) in industrial processes.

2nd contact person:

3. equipment:

CFD software:

- ANSYS Academic Teaching Mechanical and CFD

- ANSYS Academic Research Mechanical and CFD

Hardware:

- Use of the computers in PC Pool I and II

- Special customised workstation for complex calculations

(e.g. simulation of fluid-structure interaction) - PC cluster for extensive multiphase simulations

4. laboratory exercises:

- Several examples / projects for the simulation of flow and heat transport phenomena

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

In logistics and material flow optimisation, discrete event-driven simulation is the tool of choice when it comes to dynamic processes. The exercise provides an introduction to the professional tool PLANT SIMULATION, which has prompted and enabled numerous students to successfully use the system in their projects and theses. Students can download an academic licence (NON-PROFIT licence) free of charge.

Contact person:

Prof. Dr.-Ing. Wilhelm Petersen

Prof. Dr.-Ing. Hein-Petersen Landvogt

Equipment:

DES Software: PLANT SIMULTION (floating licence bundle of 25 licences)

Hardware: Use of computers in PC pool I and II

Laboratory exercises:

The laboratory exercise is part of the module Materials Management Logistics.

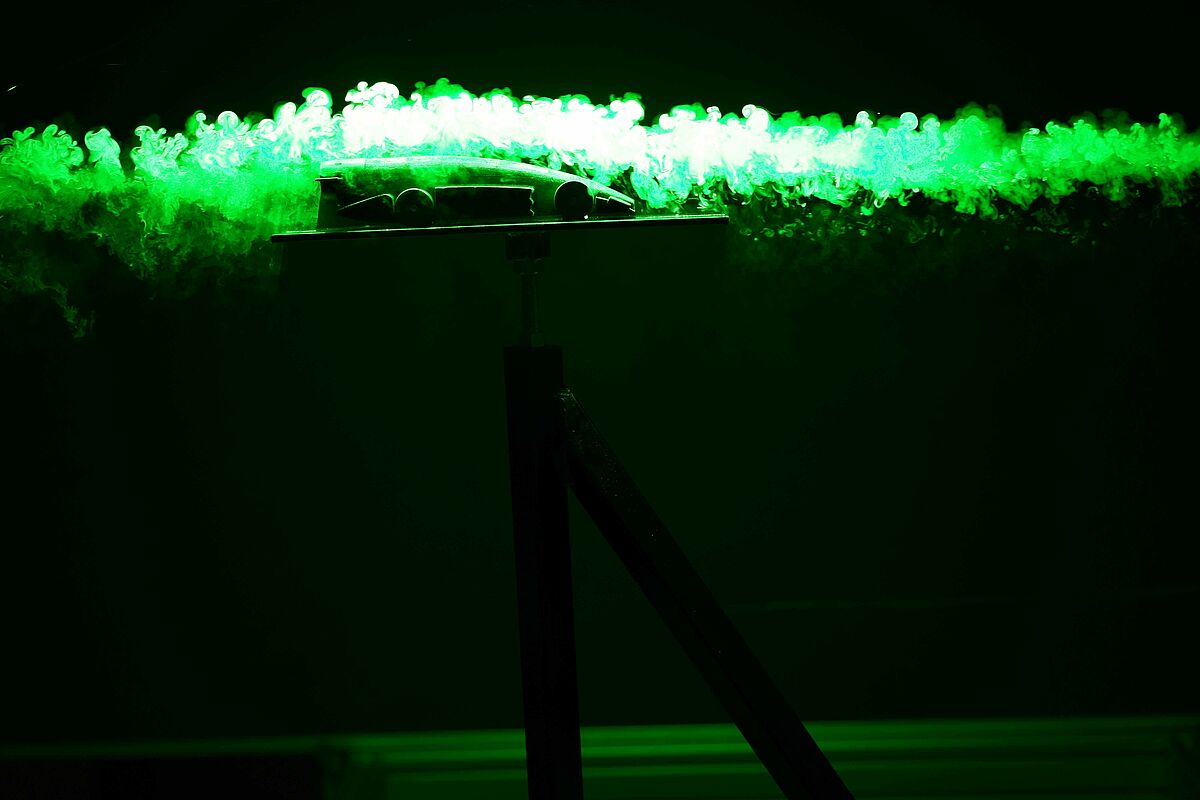

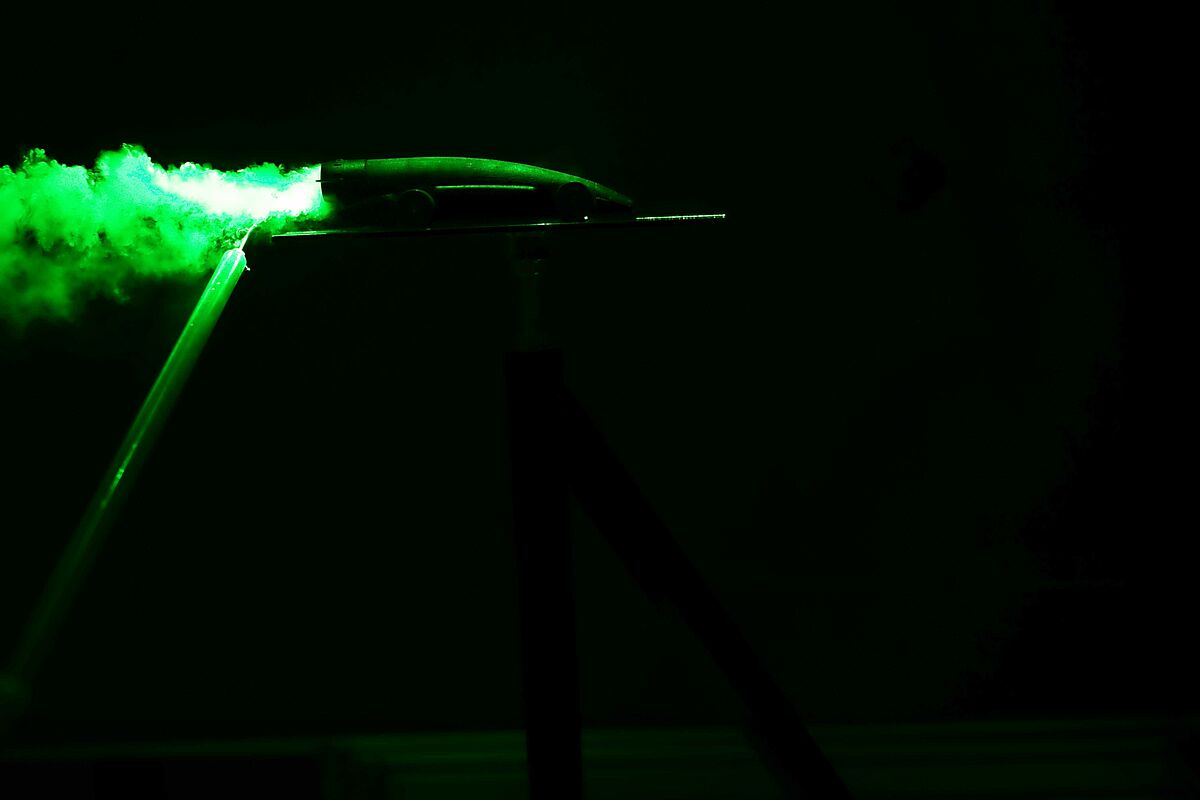

In the vehicle aerodynamics laboratory, practical experience of the flow around bodies is taught on special test rigs and knowledge of the use of modern optical, non-contact velocity measurement technology (PIV and LDA) is demonstrated.

The flow field and air forces of test objects (e.g. vehicle models) can be realistically analysed in a large circulating wind tunnel.

Contact person:

Equipment:

- Circulating wind tunnel (Göttingen design, measuring cross-section 0.7 x 0.7 m, max. speed 55 m/s)

- Particle Image Velocimetry System,

Laser Doppler Anemometry System - Conventional pressure and velocity measurement technology

- Measuring system for dynamic measurement of flow resistance

(3-component and 6-component strain gauge balance)

Laboratory exercises:

- Design and function of wind tunnels

- Flow around bodies - Flow resistance

- Optical flow measurement technology (PIV and LDA)

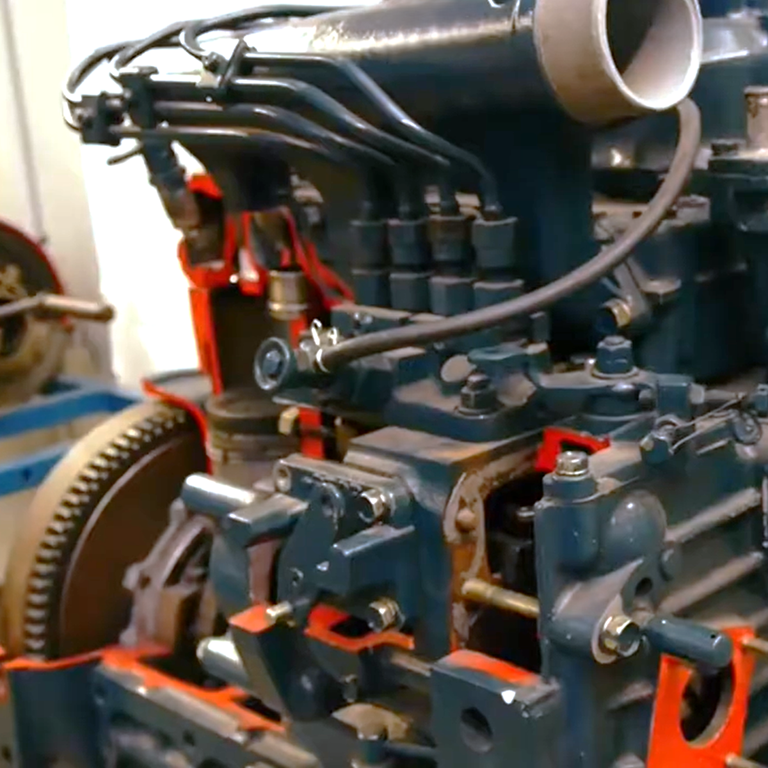

In practice, deepening knowledge of the structure, function and interaction of mechatronic vehicle systems through practical exercises with measurement and diagnostic technology on individual components and motor vehicles as well as learning the universal applications of a service and information system of vehicle equipment suppliers.

Contact:

Prof. Dr Jens Ladisch

Laboratory staff:

Dipl.-Ing. (FH) Ulf Steinfurth

Regularly held courses:

Torque management system and strategies in the ECU

Ignition management system and strategies in the ECU

Injection management system and strategies in the ECU

Equipment:

- On-board diagnostic system KTS 570 (BOSCH)

- ESI[tronic] service and information system (BOSCH)

- CAN bus teaching system (ELWE)

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

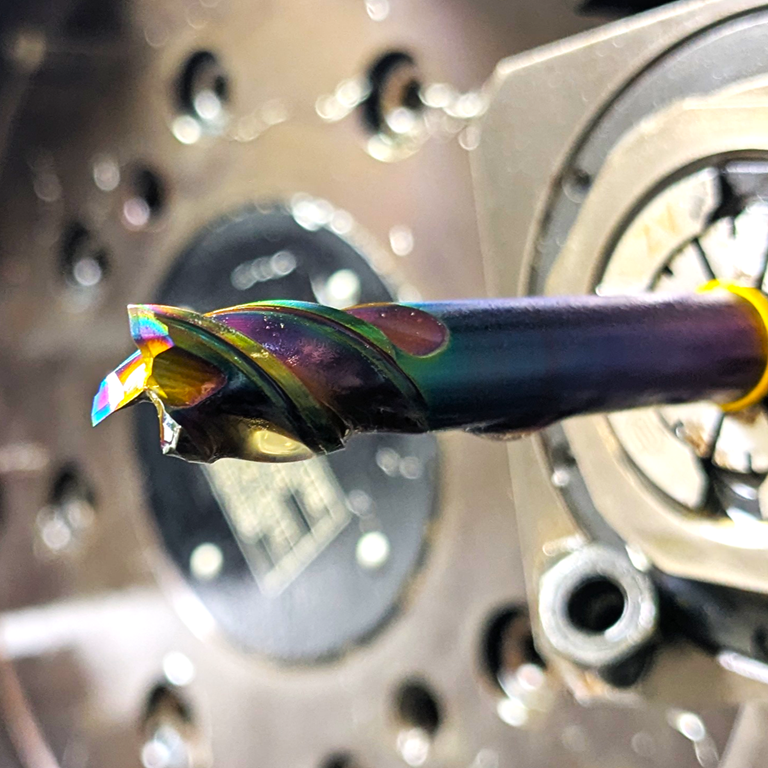

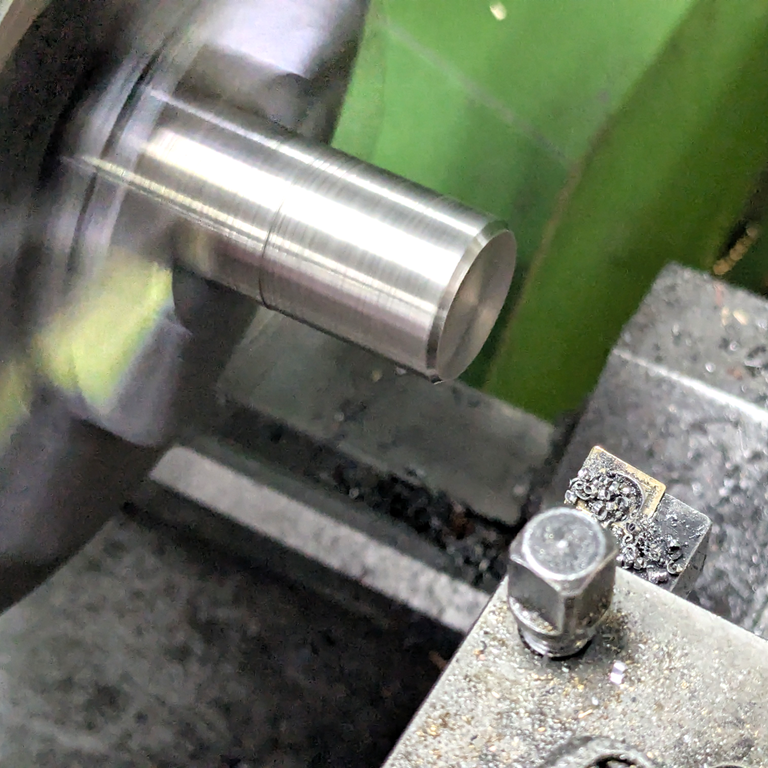

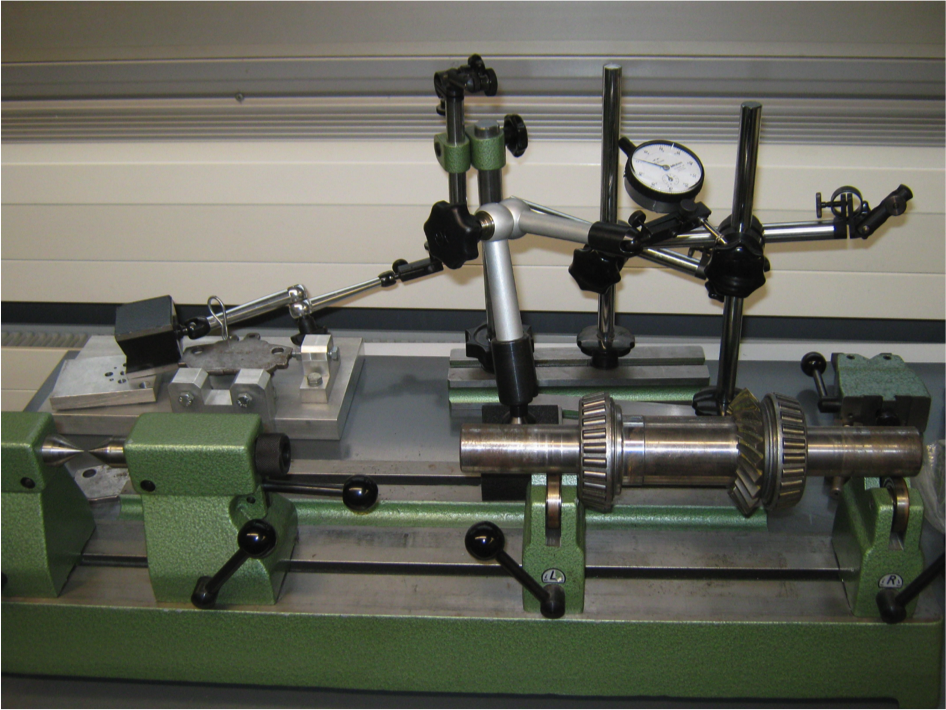

The aim of the production technology laboratory is to familiarise students with important manufacturing processes and the possible applications of the associated machines. Students put what they have learnt in theory into practice by taking part in laboratory practicals in small groups, in which they acquire special knowledge of the relationships between materials and manufacturing processes under supervision. State-of-the-art NC-controlled machines for machining, forming and non-cutting processing enable extensive teaching and research in the fields of production technology, machine tools and intelligent networking (Industry 4.0) on approx. 250 square metres of laboratory space. The laboratory is rounded off by the possibility of casting aluminium using the sand casting process. Project, Bachelor's and Master's theses can use all of the laboratory's facilities.

Contact person:

Equipment:

- Conventional and NC lathes

- 5-axis NC machining centre

- Tool presetter - Laboratory roller millTool presetter

- Laboratory roller 0.5 MN (50 t) up to 600°C

- Universal tool grinding machine, LehreningUniversal tool grinding machine, jig boring machine

- Die-sinking EDM machine

- Hydraulic press (1.6 MN, 160 t)

- 3-component cutting force measuring platform

- Sound level meter, 2-channelSound level meter, 2-channel FFT analyser, storage oscilloscope

- Force, displacement and vibration measuring equipment

- Strip projector, other measuring and analysis equipment

- Hot and cold tensile testing machineHot and cold tensile testing machine

- Vibration corrosion test bench

- Aluminium sand casting test station

- 3D powder printer

Laboratory exercises:

Machining technology:

- Cutting force measurement on a conventional lathe

- Investigating the stability limits of a lathe

- Programming and operating NC lathes and the NC machining centre

- CAD-CAM couplingCAD-CAM coupling

- Performance, working accuracy and environmental behaviour of machine tools

- Machining of hard components with electroerosive countersinking

Forming technology:

- Upsetting of different metallic materials in the taper upsetting test (determination of friction, deformation resistance and degree of deformation)

-Factors influencing the deep drawing of sheet metal

- Rolling of sheet metal

- Manufacturing processes for the production of stamped parts

Casting technology:

- Sand mould casting of aluminium and magnesium alloys

- Hand forming

- Machine forming

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

The fundamentals of fluid mechanics for incompressible fluids are illustrated using fluidic systems (water and air systems) and practical experience is gained.

In the laboratory, experimental investigations are carried out independently in the group after instruction and guidance by the laboratory engineer with appropriate division of tasks. The recording of parameters of various fluids in different operating conditions is the subject of the laboratory course. The results are analysed and interpreted by engineers and presented in an overall report.

Contact person:

Equipment

- Conventional velocity and pressure measurement technology

- Pipeline test rig for incompressible media (water) with various integrated pumps, valves, measuring devices and pipelines

- Pipeline test rig for compressible media (air) with connected radial fan and various attachments and measuring equipment

- Test rig for demonstrating various flow measurement methods

- Test rig for determining pressure losses

Laboratory exercises:

- Air flow

- Water flow

- Velocity distribution in pipe flows

- Pump and system characteristic curve

- Parallel and series connection of pumps

Theoretical relationships and practical experience of fluid mechanics in compressible flows are taught on various test rigs and systems. The subject of the experiments is the measurement of various flow parameters such as temperature, pressure and density. These vary under different operating conditions and flow processes.

In the laboratory, experimental investigations are carried out independently in the group after instruction and guidance by the laboratory engineer with appropriate division of tasks. The results are analysed and interpreted by engineers and presented in an overall report.

Contact person:

Equipment:

- Data logger for conventional temperature and pressure measurement technology

- 16 - channel pressure and temperature scanner

- Test rig for determining flow variables in convergent nozzles

- Test rig for determining flow variables in Laval nozzles

- Test rig for the determination of jet forces

- Test rig for determining the efficiency of different nozzles

Laboratory exercises:

The following experiments are offered in the Fluid Mechanics II laboratory:

- Flow parameters in convergent nozzles

- Flow parameters in Laval nozzles

- Efficiency of different nozzles

- Jet forces through different nozzles

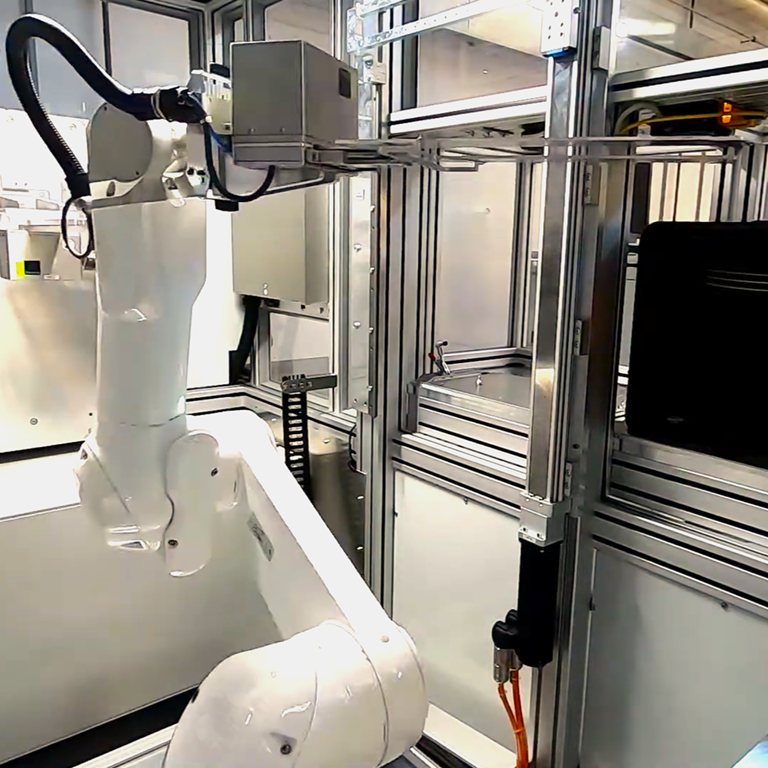

In the laboratory, students learn about the design, mode of operation and programming of industrial robots and mobile systems. The handling and programming of robots and traversing units can be learnt realistically using the existing robot systems.

Contact person

Equipment

ABB IRB 4400 robot with translatory traversing axis

TOX push-through feeding system

Robot cell

Conveyor system from FLEXLINK

Laboratory exercises

Design and mode of operation of an industrial robot (ABB IRB 4400)

Programming an industrial robot (ABB IRB 4400)

Application of an insertion system from TOX Pressotechnik

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Welding and soldering join metals, often through the energy of the glistening electric arc. Aim of the lab: All mechanical and industrial engineering students must have used a welding torch to create a weld and understand the theory behind it.

2nd contact person:

- Prof. Dr.-Ing. Normen Fuchs (European Welding Engineer)

- Dipl.-Ing. Ronny Bleiß (European Welding Engineer)

3. equipment:

- Soft and hard soldering

- Gas welding and oxygen flame cutting

- Welding power sources for manual electrode welding

- Metal inert gas and metal active gas welding (MIG and MAG)

- Tungsten inert gas welding (TIG)

- Spot welding

- Stud welding

- NC plasma cutting portal

- Electrical measurement of the welding process

- Quality data from welding processes

Laboratory exercises:

Occupational safety

- Current and voltage

- UV and heat radiation, eye protection

- Welding fume extraction

- Protective clothing

Soldering

- Soft soldering

- Hard soldering

Gas welding

- Safety equipment

- Flame settings

- Working techniques

Pressure welding

- Spot welding of sheet steel and aluminium

- Stud welding with drawn arc

Fusion welding

- Manual electrode welding with different types of electrodes

- Gas metal arc welding (MAG), pulsed and non-pulsed

- Metal inert gas welding (TIG) of steel and aluminium

Thermal cutting processes:

- Oxygen flame cutting

- Plasma cutting

Measurement technology

- Arc types

- Measuring current and voltage in the welding process

- Quality data acquisition

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

The aim is to impart practical knowledge in dealing with hydraulic and pneumatic components and systems.

Topics covered include hydrostatics, hydrodynamics, servo and proportional valves, characteristic curves of hydraulic pumps and pulsation in hydraulic systems.

Contact person:

Prof. Dr.-Ing. Joachim Venghaus

Equipment:

Hydraulics teaching and training system

Test bench high-pressure hydraulic system

Multi-measurement system 5000 (pressure, temperature, volume flow, speed)

Various sensors (pressure sensors, temperature sensors, pulse sensors, etc.)

Frequency generator, frequency counter, oscilloscope

BMC measured value acquisition system

MGC measuring amplifier system

Laboratory exercises:

Influence of viscosity changes on hydraulic components

Determination of Reynold's number

Efficiency of hydraulic systems

Pulsation/pressure peak measurements with the aid of strain gauges

Determination of pressure drop via filters, various valves and pipework types

Determination of hydraulic power

Determination of characteristic curves of various pumps, motors, valves and installation elements

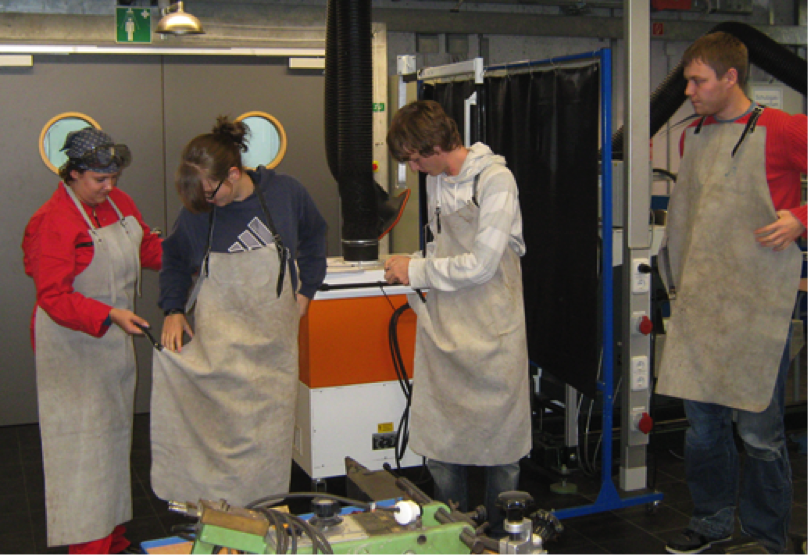

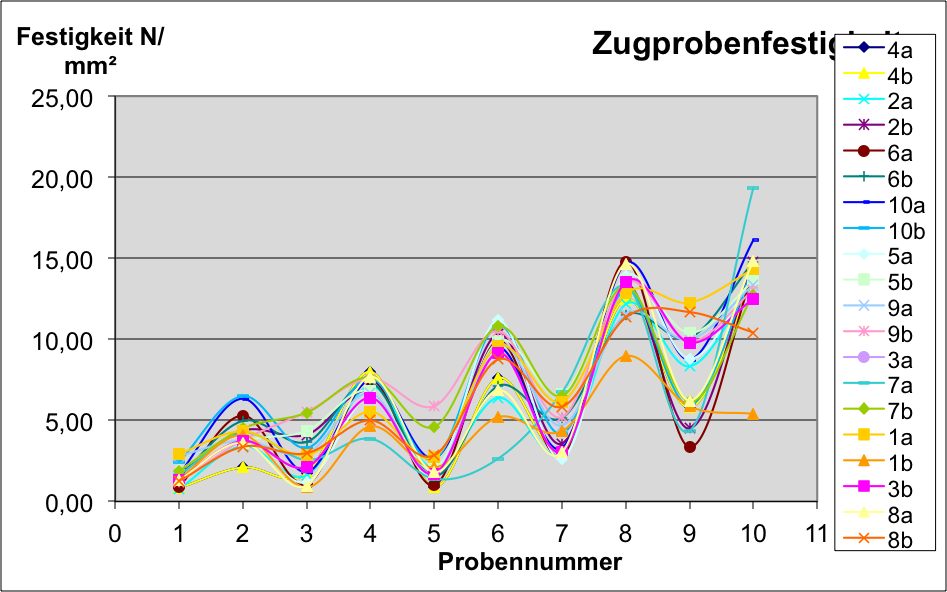

Bonding metals and non-metals is a joining technology with a future. Without the influence of heat, high-strength joints can be produced from a wide variety of materials. All mechanical engineering and industrial engineering students should have carried out the preparation and production of bonded joints in theory and practice and then tested the strength of the joints.

Contact person:

- Prof. Dr.-Ing. Normen Fuchs

- Dipl.-Ing. Ronny Bleiß

Equipment:

Bonding:

- Gluing workstations with extraction

- Adhesive storage cabinet, cooled

- Sandblasting unit

- Ultrasonic cleaner

- Roughness measurement

- Cold plasma surface activation

- Tensile testing machine 10 kN

- Laboratory fume cupboard and chemical storage cabinet

- Emergency showers for eyes and body

Plastic welding:

- Socket welding

- Mirror welding

- Hot gas welding

- Pressure testing of pipe welded joints

Laboratory exercises:

Occupational safety

- Skin and eye protection

- Solvent extraction

- Protective clothing

Bonding:

Overlap adhesive joints

- Metal-metal

- Metal-plastic

- Adhesive type/bonding mechanism

- Stress curve in the bonded joint

Sample preparation

- Degreasing only

- Degreasing and grinding

- Degreasing and corundum blasting

- Plasma activation

Testing:

- Measurement of the samples

- Tensile test with force determination

- Determination of the maximum shear stresses

- Assessment of the fracture surfaces

Plastic welding:

- Blunt pipe joints

- Pipe joints lugged

- Pressure testing of pipe joints

- Hot gas welding of panel materials

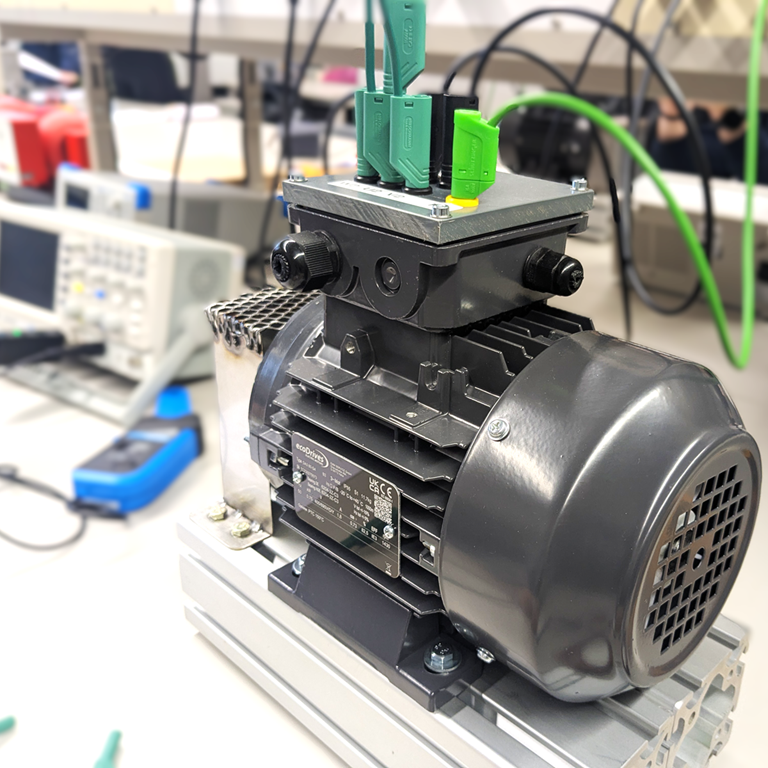

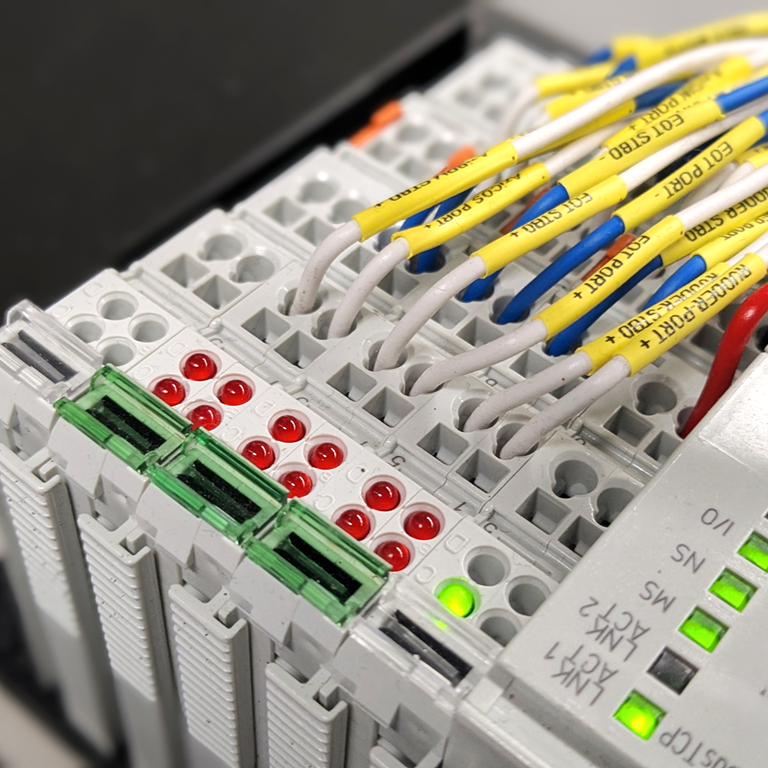

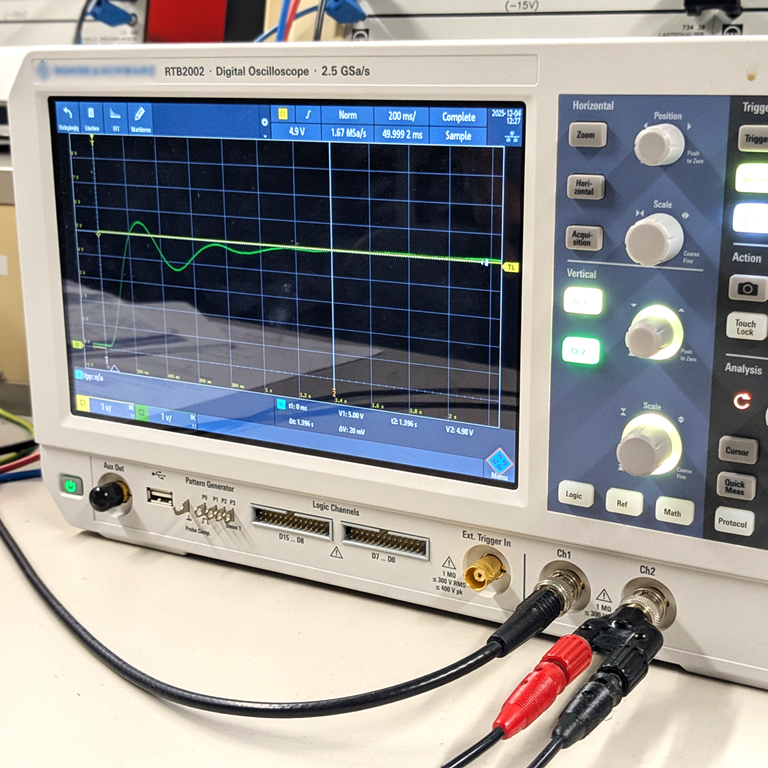

Ultimately, every measurement is based on a physical effect. Students learn how measurement technology makes use of these effects and minimises interfering influences that distort the result through a clever measurement setup. The second focus is on analogue and digital measured value processing, including error analysis and mathematical evaluation on the computer. In a third focus, students will familiarise themselves with dynamic systems from a laboratory perspective and in this way complete the knowledge of systems theory taught in the measurement technology lecture.

The exercises deal with so-called electrical measurement technology, whereby the focus is mainly on the acquisition of non-electrical variables.

Contact person

Equipment

Hardware

Oscilloscopes - analogue and digital storage oscilloscopes with bandwidths of up to 500 MHz or sampling rates of 4 GSa/s.

Function generators - 15 MHz and 3 MHz

Digital multimeters

IR thermometers - infrared, -40 °C to 260 °C;

Thermocouple measuring station - type K thermocouple with analogue and digital measured value processing, GPIB bus, LabVIEW

Strain gauge amplifier systems - up to 6 measuring points, DC voltage and carrier frequency measuring amplifiers

Digital signal processing

Bus systems - GPIB (IEC-625), RS-232, USB

Experiment control, measurement conversion and display - LabVIEW, visual development environment, National Instruments

Evaluation - Mathcad

Laboratory exercises:

Use of strain gauges - specific resistance, modulus of elasticity, bending moment, Poisson's ratio, Wheatstone bridge, measuring amplifier, characteristic curve, error calculation

Temperature measurement - Seebeck effect, thermocouple, forward current of a diode, temperature dependence, semiconductor sensor, NTC elements, resistance thermometer (Pt100)

Dynamic characteristic values of a first-order system - system theory, step response, time constant, thermocouple, GPIB, LabVIEW

Position and speed measurement - potentiometric displacement measurement, incremental speed sensor, motor-generator arrangement, intelligent sensors, fieldbus protocols

Introduction to digital measurement technology - bistable flip-flops, logic gates, dual numbers, BCD, counting circuits, digital-to-analogue converter (DAW), digital storage oscilloscope (DSO)

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Equipment:

The following equipment is available for use in PC Pool I:

- 16 PC workstations with the following equipment:

- 27'' TFT monitor Dell (2 units)

- Dell Optiplex 5040, 3.3 GHz, 16 GB

- Dell keyboard

- Logitech laser mouse

- 3DConnexion SpaceExplorer

- 1 Epson 2480 flatbed scanner

- 1 b/w laser printer Kyocera FS 9130DN

The following software is available for use in PC Pool I:

- MS Windows 7 operating system

- MS Office 2010

- MS Visual Studio

- Corel Draw X5

- SolidWorks

- Cadenas Partsolutions

- Mathcad Prime

- Matlab

- ANSYS Fluid Module

- Plant Simulation

- IPG Carmaker

A teacher/student circuit is installed in all pools. All pools are equipped with air conditioning so that students can work comfortably even in summer. The doors have been fitted with programmable transponder locks to provide 24/7 access for students (outside of classes).

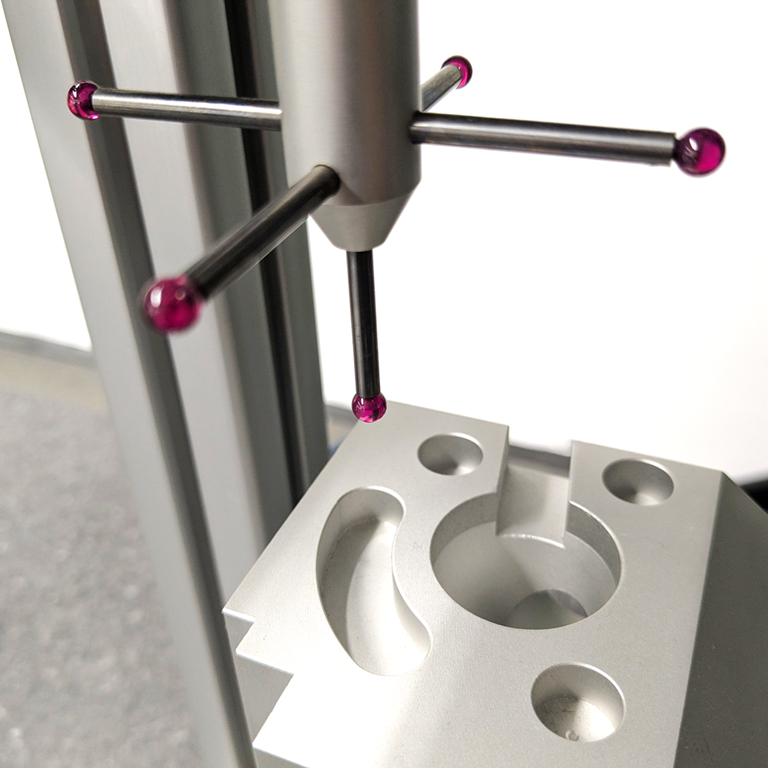

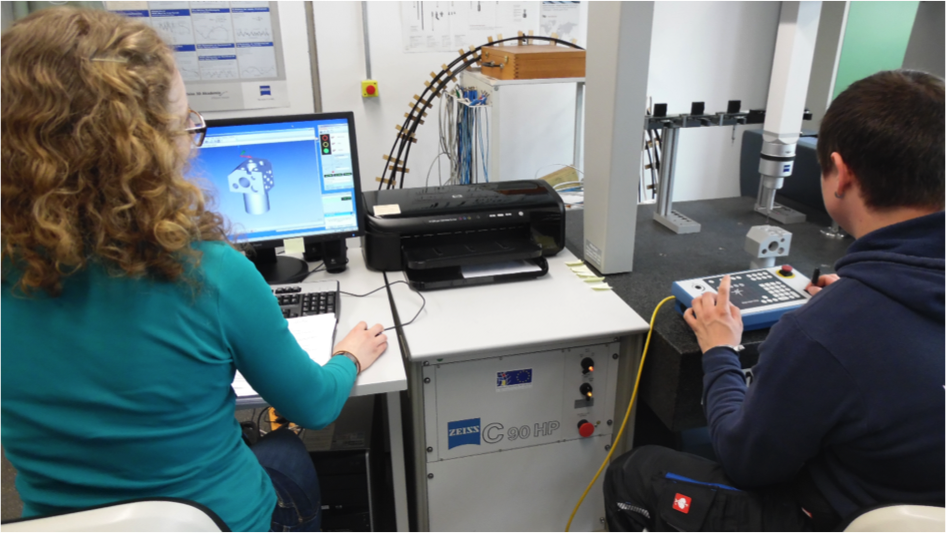

Measuring equipment is indispensable in modern production in order to be able to verify the quality of manufactured products. Students learn how to operate measuring equipment and are familiar with the processes involved in monitoring and calibrating measuring equipment. The main machine in the laboratory is an NC-controlled 3D coordinate measuring machine.

Contact person:

- Prof. Dr.-Ing. Normen Fuchs

- Prof. Dr.-Ing. Jens Ladisch

- Dipl.-Ing. Ronny Bleiß

Equipment:

- CNC 3D coordinate measuring machine Zeiss Eclipse

- 3D scanner for capturing free-form surfaces

- Measuring equipment and standards for production metrology

- Internal measurement

- External measurement

- Roughness measurement

- Roundness measurement

- Digital measurement data acquisition and evaluation

- QM software

- Concentricity testing

Laboratory exercises:

- Tools and methods of quality management

- Capability tests

- Statistical process control (SPC)

- Test equipment monitoring

- Measuring system analysis

- Application of coordinate measuring technology

- Scanning of free-form surfaces

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Based on thermodynamics, fluid mechanics, apparatus engineering, measurement and control technology, the interdisciplinary relationship between the functions and structure of technical equipment for air design in the context of ventilation and air-conditioning technology is dealt with.

Contact person:

Prof. Dr.-Ing. Franka-Maria Mestemacher

Equipment:

- "Professional" ventilation wall for setting up ventilation ducts

- Industrial air conditioning system

- Heat recovery system

- Jet fan

- Blower door measuring kit

- Diagnostic systems

Laboratory exercises:

- Characteristics of a ventilation system

- Ventilation duct design

- Air conditioning system 1: Components and mode of operation

- Air conditioning system 2: System characteristics, heating and cooling, humidification and dehumidification

The integration of computer technology has become an integral part of a company.

The data that can be generated, managed and analysed for the entire order processing of a product in various process stages is applied and presented in business management systems using the example of a virtual company.

Microcontrollers of various types are used to network different machine models, sensors and mobile devices.

Contact person:

- Prof. Dr.-Ing. Christine Wahmkow

Equipment:

In the laboratory:

- 5 PC workstations with the latest equipment

- Various Arduino microcontrollers

- 3D printer Vellemann K8200 converted to chocolate printing

- 3D printer Anet A8

- 3D camera Microsoft Kinect 1 & 2

Laboratory exercises:

- Rough planning using MS-Project

- Bottleneck avoidance using Excel Solver

- Order processing using Odoo

- Projects in the content of Industry 4.0 using Arduino

Students are introduced to the basic concepts of control engineering. They learn about the time response and frequency response of P, PT1, PT2 and PTn transfer elements. The time behaviour of complete control loops is examined. In this way, students acquire knowledge of P, I and D control behaviour. The concepts of control quality and stability are deepened. Analyses are carried out using graphical methods as well as MATLAB/Simulink and Mathcad.

Contact person

Equipment

- Speed control of a motor-generator set - modular teaching system, 100 W motor-generator set,

- analogue PID controller

- Speed and position control of a servo motor - modular teaching system, digital PID controller,

state controller

- Temperature control - teaching system

- Tank model - industrial components

- Controlled system models

- PC technology with special software - MATLAB/Simulink and xPC target for controller design

- Measurement technology - dual-channel recorders, digital storage oscilloscopes, multimeters

Laboratory exercises

- 1st and 2nd order system - PT1 and PT2 system in the time and frequency domain

- Speed control - electric motor, motor-generator arrangement, load

- Investigation of PTn behaviour- PTn system, heating model

- Simulation of transfer elements and control loops - Numerical simulation, Mathcad and

MATLAB/Simulink

- Temperature control - soldering iron, compact controller

- Level control of a tank - tank model, computer-aided mapping of the time curves of controlled and manipulated variables

- Two-point control - PC simulation with block-orientated software

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

In the cleanroom technology laboratory, students learn about the structure, mode of operation and operation of cleanrooms of the highest classes. The focus is also on regulations on behaviour in cleanrooms, dress codes and particle measurements on conveying and handling equipment.

The laboratory is also used for research work on automated flexible and versatile mobile robot systems(Productive4.0)

Contact person

Equipment

Clean room class ISO 7/8 with 40 m² test area

Clean room cabin class ISO 3 /GMP 20m²

Flexible and self-sufficient robot module with KUKA LRB4+

Robot cell "Contactless wafer handling" with Stäubli TX60L CW and ultrasonic wafer gripper ZS-

AGV Adept MT 400

AGV with contactless energy supply (self-built by HS Stralsund with SEW)

Mecanum-AGV Imetron / Ventum-S

2x AEROTRAK particle counters

1x Lasair III particle counter

KUKA KMR-IIWA

Laboratory exercises

Regulations and dress code in cleanrooms

Design and operation of cleanrooms

Particle measurements for the qualification of cleanrooms

Particle measurements on conveyor and robot systems

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Practical experience and theoretical correlations of fluid energy machines/flow machines are taught on various test rigs and systems. The subject of the experiments is the measurement of various parameters of the turbomachinery in different operating states. These practical experiments are used to illustrate the basic knowledge of different turbomachines for different fluids and different processes.

In the laboratory, experimental investigations are carried out independently in the group after instruction and guidance by the laboratory engineer with appropriate division of tasks. The results are analysed and interpreted in an engineering manner and presented in an overall report.

Contact person:

Equipment:

There are various test rigs in the laboratory:

- Group 1, general turbomachinery:

-

- Test rig for radial fans and radial blowers

- Water pump trainer

- High-speed compressors

- Group 2, water turbines

-

- Test rigs for radial turbines

- Test rigs for axial turbines

- Group 3, gas turbines

-

- 190 kW loading device

- Model of a small gas turbine

- Gas turbine type Pirna GT 028-1

The measurement technology in the laboratory consists of, among other things

- DL716 analyser recorder (Yokogawa)

- Digital storage oscilloscope (Hewlett Packard)

- Measurement data acquisition system with PC coupling

Laboratory exercises:

Experiments from the different groups of turbomachinery are offered as part of the course Turbomachinery:

- General turbomachinery through various radial fans and radial blowers, various centrifugal pumps and a side channel pump

- Water turbines represented by experimental models of a radial reaction turbine, an axial impulse turbine, a Pelton turbine and a propeller turbine

- Gas turbines represented by a small gas turbine and a Pirna GT 028-1 gas turbine

- High-speed compressor map

In the flow measurement technology laboratory, the basics of various invasive and non-invasive flow measurement methods are taught and can be applied to different configurations. They are used for special applications in teaching (as part of Bachelor's and Master's theses) and for research projects. They provide the link to the results of numerical flow diagnostics.

Contact person:

Equipment:

There are various test rigs in the laboratory:

- HS 4540 high-speed camera system (Kodak) - 40500 images/s

- Particle Image Thermometry - System - 3 chip colour CCD camera 512 x 512, 24Bit

- Measurement data acquisition systems with PC coupling

- Particle Image Velocimeter ( 180 mJ/pulse ND Yag Laser)

- 1-dimensional ultrasonic Doppler velocimeter

- 2-dimensional laser Doppler anemometer

- 3-dimensional phase Doppler anemometer

- High-power xenon lamp (20000 lumen)

Laboratory exercises:

The Department of Fluid Mechanics and Fluid Machinery offers advanced and in-depth laboratories in the higher semesters:

- Optical Fluid Dynamics LDA

- Optical flow measurement technology PIV

- Acoustic Fluid Dynamics UDV

- Applied Fluid Mechanics

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.